Do HVLS Fans Risk Fire Safety?

![]() High-volume, low-speed (HVLS) fans require little energy to ventilate large commercial and industrial buildings, and their use can result in considerable cost savings to business owners. But do they compromise fire safety? What are the codes requiring?

High-volume, low-speed (HVLS) fans require little energy to ventilate large commercial and industrial buildings, and their use can result in considerable cost savings to business owners. But do they compromise fire safety? What are the codes requiring?

Only recently test results from full-scale fire tests have become available to the design community and regulated industries to help evaluate building fire safety when HVLS fans are installed.

However, there are a multitude of questions to be answered such as, can these large fans compromise sprinkler performance i.e., can and do they impede sprinkler operation? Do I lose the benefit of ESFR or CMDA systems for commodity protection? Will this in turn impact storage arrangements in warehouses? What are the installation requirements based on the latest codes and regulations? In other words, on which grounds can the installations be considered ‘safe’ for a given building scenario?

In this article we would like to present concerns of the fire safety community regarding HVLS fan use for commercial and industrial buildings and their effort in addressing them through full-scale fire tests. We will review the latest knowledge from fire testing and code requirements for the installation of HVLS fans.

High-Volume Low-Speed Fans

High-volume low-speed (HVLS) fans were developed to provide considerable energy savings when used alone or in conjunction with conventional heating, ventilation and air conditioning systems. Their installation and use can be highly economical especially when applied in large commercial and industrial buildings, where energy costs comprise a large portion of the overall operating budget.

High-volume low-speed (HVLS) fans were developed to provide considerable energy savings when used alone or in conjunction with conventional heating, ventilation and air conditioning systems. Their installation and use can be highly economical especially when applied in large commercial and industrial buildings, where energy costs comprise a large portion of the overall operating budget.

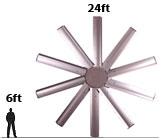

The fans’ specially designed airfoil blades move slow (hence “low-speed”) but can run up to 12 feet in length each resulting in a max. of 24 foot diameter for the largest fans. As a result, these gigantuous fans are capable of moving a large air volume (up to 400,000 cfm) very efficiently – while requiring as little as ½ KW for their operation. Without a doubt, these are powerful fans that are economical to operate.

The fans’ specially designed airfoil blades move slow (hence “low-speed”) but can run up to 12 feet in length each resulting in a max. of 24 foot diameter for the largest fans. As a result, these gigantuous fans are capable of moving a large air volume (up to 400,000 cfm) very efficiently – while requiring as little as ½ KW for their operation. Without a doubt, these are powerful fans that are economical to operate.

What are the Concerns with HVLS Fans?

Since the introduction of HVLS fans in the mid nineties, insurance agencies, code regulators, and fire safety communities have been concerned about their impact on fire safety. There are two main concerns

(1) Do HVLS fans obstruct sprinkler operation in case of fire by effectively reducing

the amount of water reaching the fire and

(2) Does their additional air flow produced while in operation increase fire spread

or negatively impact overall fire dynamics?

Both of these concerns are very serious and if not successfully addressed in the design can lead to catastrophic events in case of a fire. Lets review these concerns in some more detail and explain how they might impact building safety and business investment in warehouses.

Do HVLS Fans Obstruct Sprinkler Spray?

These fans can produce a powerful downward stream of air i.e., several 100,000 cfm. Upon sprinkler activation the spray discharge created by the water striking the deflector produces a large diameter of water droplets in the same direction. On first glance it does not seem far-fetched to assume that these two ‘streams’ may impact each other.

Is it possible that with a fan operating the effective sprinkler discharge radius is reduced or large water droplets created by ESFR sprinkler heads are reduced to smaller ones with less momentum? Could this diminish the ESFR sprinklers, effectively create a “control mode” sprinkler system, which does not extinguish fires but rather controls it (until fire fighters will arrive to extinguish the fire)?

The blades themselves, rotating at a slow speed but potentially creating a “canopy” that can obstruct the stream of water droplets (downward), may limit or prevent the required volume of water from reaching the fire in time for suppression to commence.

Considering that ESFR sprinkler systems are typically more expensive, this would mean that their fire extinguishing effectiveness might be reduced to more closely resemble a “control mode sprinkler system”. Additionally the fire code provides incentives for installing ESFR systems, such as longer travel distances and elimination of smoke and heat vents. These benefits may need to be reevaluated with the installation of HVLS fans.

Do HVLS Fans Impact Fire Spread?

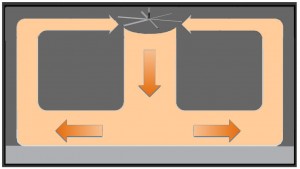

Anyone having been in a large building with these fans in operation probably noticed a horizontally moving air column, a so-called floor jet. Similar air movement can be observed near the ceilings or above the HVLS fan. The dynamics of the floor and ceiling jets are related to the air foil or blade shape, fan diameter and the rotation speed of the fan. When an obstruction is encountered, these jets are reduced in strength but they do not completely stop – rather they continue to flow through and circulate any obstructions in their path. In part this is what makes HVLS fans so effective.

Anyone having been in a large building with these fans in operation probably noticed a horizontally moving air column, a so-called floor jet. Similar air movement can be observed near the ceilings or above the HVLS fan. The dynamics of the floor and ceiling jets are related to the air foil or blade shape, fan diameter and the rotation speed of the fan. When an obstruction is encountered, these jets are reduced in strength but they do not completely stop – rather they continue to flow through and circulate any obstructions in their path. In part this is what makes HVLS fans so effective.

Do small fans have the same issues? Not really, as the depth of the jet (in case of the floor jet this is the distance from floor to the top layer of the horizontally moving air layer) is primarily dependent on blade size. Small blades simply cannot produce similarly sized jets as HVLS fans do.

We must also consider the vertical air column between the floor and the HVLS fan. If a fire is started within the “downdraft” area of the large vertical column wouldn’t that feed the fire with oxygen and change the fire dynamics? What is the impact of flue spaces in storage configurations on fire spread in presence of the air stream produced by a HVLS fan? Does the air column affect fire behavior under different storage configurations such as the flue spaces of palletized storage or the flue spaces in storage racks?

Full-Scale Fire Tests

It seems that all of these concerns are well founded and therefore it was only a matter of time until several fire tests were planned and conducted, with the latest one performed in 2010.

XL Gaps Fire Tests

In October 2007 XL Gaps (Global Asset Protection Services) initiated full-scale fire tests at Underwriter Laboratories using palletized and rack storage arrangements of plastic and cardboard commodities on wooden pallets to study how HVLS fans may affect sprinkler performance.

The first series of tests were performed for palletized storage using

- Extra Large Orifice (ELO) control mode sprinkler protection for Group A plastics commodities stored to a height of 15-feet underneath a 25-foot ceiling, and

- Control mode sprinkler protection for Class II commodities stored to a height of 12-feet underneath a 22-foot ceiling

- In both tests the ignition source was located between four ceiling sprinklers

The second series of tests were performed using ELO sprinkler protection for rack storage of Group A plastic commodities stored to a height of 15-feet underneath a 25-foot ceiling. Ignition was located in the flue space of the rack directly below the tip of the fan blade for rack storage; fan location was varied between this series of second tests.

In all of the fire tests fan power was shut off after the first sprinkler operated and the fan was allowed to coast to a stop. Fans were operated at 50% capacity.

These full-scale fire tests results were not very promising. In the case of the Group A plastics stored in racks the HVLS fan delayed the operation of the ceiling sprinklers; for palletized storage the results were worse, resulting in uncontrolled fire spread for the stored Group A plastics storage.

However, the observations and results of these tests suggested to continue the effort in understanding HVLS impact on sprinkler performance and to study the “break points of the influence of HVLS fans and palletized storage heights” (complete test report(1) available from NFPA).

Phase I Fire Test

Following this suggestion, the Fire Protection Research Foundation of the National Fire Prevention Association (NFPA) conducted multiphase full-scale fire tests, with Phase 1 of the testing completed in 2008 and 2009, and Phase 2 of the testing completed in 2010.

In this series of tests ESFR system performance in full-scale fire testing was evaluated under practical worst-case fire conditions. The Phase I research effort(2) involved full-scale tests at Underwriters Laboratories and explored the obstruction of sprinkler discharge by HVLS fans and the required fan shut-off time.

In these tests the HVLS fan was placed between four sprinklers (considered a commonly used and practical fan placement). The tests were performed using ESFR protection of rack storage of Group-A plastics stored to a height of 20-feet underneath a 30-foot ceiling.

Two fan locations were studied in relation to the ignition point at the ceiling. A standard HVLS fan was installed and its blades were turning at standard operating speeds (up to 100% capacity).

It is noted that in these tests fan power was not linked to sprinkler activation, but was manually controlled to study the impact of fan shut-off time on fire spread. During both tests the fan was not shut off during sprinkler activation.

These two tests again confirmed HVLS fans will impact the performance of sprinkler systems negatively protecting high-piled combustible storage.

HVLS full-scale fire test for rack storage loaded with pallets and cardboard boxes with Group A plastics

(Fire Test Demonstration at Underwriter Laboratories, June 2009). Video courtesy of NFPA

Both tests received a “passing grade” for the fire scenarios investigated. When the ignition source was placed under the tip of the HVLS fan blades, the sprinkler system could suppress the fire. In this test three ESFR sprinklers operated. However, when the ignition source was centered directly beneath the HVLS fan, the fire could only by be “controlled” by eight ESFR sprinklers (but not “extinguished”), despite the fact that almost 3x times (i.e., 8 vs. 3 heads) as many sprinkler heads opened when compared to the previous test. The test received a ‘pass’, because the total number of sprinklers activated during the test was less than 12, which is an established design criterion for ESFR systems.

These test results demonstrated that a HVLS fan, depending on its location, can effectively shield the fire from the ESFR sprinkler discharge due to the fan-induced airflow. This became especially apparent within the lower tiers of the storage array where the fire burned with high intensity and was not well controlled by the sprinkler discharge.

Based on these test results, the final conclusion was that HVLS fans did not affect the performance of the ESFR sprinklers unacceptably.

Some of the conclusions and recommendations drawn from the fire tests were:

- The minimum vertical clearance between the fan blade and a sprinkler deflector at ceiling level should be 3 feet as currently allowed by NFPA 13 for clearance to storage

- It is recommended that HVLS fans be installed between 4 sprinklers

- The influence of fan-induced airflow on fire spread is a strong function of fan airflow, storage geometry, clearance from fan to storage, building height of the test facility, distance to walls and the location/spacing of additional fans

- Successful system performance was achieved without shutting down the fan in both full-scale tests (this recommendation only holds for the investigated Phase I test scenarios)

Phase II Fire Test

The Fire Protection Research Foundation conducted phase two of the research project(3,4), focusing on fire tests in facilities taller than 30 feet (40 foot ceiling height for this series of tests), using K-14 ESFR sprinkler systems, as well as K-11.2 CMDA sprinkler systems for rack and palletized storage arrays of cartoned unexpanded Group A plastics.

This extensive undertaking of evaluating the impact of HVLS performance involved ten full-scale fire tests. Seven of the tests were performed with K-14 ESFR sprinklers at the FM Global Research Campus (FM1-4) and Underwriter Laboratories (UL-1, UL-2, UL-6), the remaining three tests involved K11.2 CMDA sprinkler systems at the Underwriter Laboratories (UL3-5).

ESFR Sprinkler System Performance

The first set of four ESFR tests (FM1-4, videos FM1-4) studied the impact of HVLS fans on rack storage array configurations, whereas the UL tests studied ESFR performance for palletized storage configurations. These series of tests showed a mixed outcome.

The following pass/fail criteria were established for the ESFR sprinkler tests

- A maximum of eight sprinklers activate

- The fire is generally contained to the ignition array

- Ceiling gas temperatures are such that exposed structural steel would not be endangered

For 30-foot high rack storage with a 10-foot clearance to the ceiling (40-foot ceiling height for all performed fire tests), the fan at full speed and no shutdown after sprinkler activation, K-14 sprinklers could not suppress the fire(s) with 12 sprinklers opening during testing (FM1, FM2) and as a result the tests received a fail grade (according to the established sprinkler criteria of allowing only eight open ESFR sprinklers). Changing the ignition location from underneath of the tip of the fan blade (FM-1) to the center of the fan (FM-2) showed little difference in the outcome, but confirmed from Phase I tests that the center location for the ignition source (under the fan) presents the most challenging situation. In both tests the fire jumped the aisles.

The following two tests (FM3, FM4) investigated the impact of fan shutdown on ESFR sprinkler performance with the remaining test conditions being similar to FM1 and FM2. The fan was de-energized after a 90-second delay upon waterflow of the first sprinkler. Only four sprinklers opened during these tests, which subsequently suppressed the fires resulting in a passing grade. FM4 studied the impact of reduced storage height from 30 feet to 15 feet under the same test conditions as FM3 (with a 90-second delay fan shutdown), the outcome was very similar, only four sprinklers opened, the fire was suppressed by the K-14 sprinkler system, with the only difference that the rack storage array took less damage than under FM3 test conditions.

Three more tests (UL-1, UL-2, UL-6) were performed for ESFR sprinklers systems. In these cases palletized storage to a height of 15 feet was investigated simulating conditions found within picking and receiving areas. Again K-14 sprinklers were used, the locations for the ignition source was ‘underneath the tip of the blade’ and ‘centered,’ the fans were not shut down during the duration of the tests. UL-1 and UL-2 investigated the impact of ignition source location, both tests demonstrated large damage to the palletized storage arrays (equivalent to 23 and 25 pallet loads respectively) despite only six ESFR sprinklers opening, which were able to suppress the fire(s).

UL-6 studied the impact of fan characteristics and the test is considered to show only little difference and “did not influence the performance of the sprinklers in a substantial manner”. However during this test the damage to the storage array was even higher than in the two previous tests (UL-1, UL-2) and consumed 28 equivalent pallets. 8 sprinklers opened (the limit to receive a passing grade). Furthermore, it must be noted that the location of the ignition source for this test was not what is considered worst-case!

Control Mode Density Area Sprinkler System Performance

The 2007 XL Gaps fire tests demonstrated that CMDA sprinklers used for palletized storage were inadequate to control the fire. The remaining last three UL tests (UL-3, UL-4, UL-5) were performed to re-investigate some of these test outcomes, as well as to gain further understanding in this type of application.

The following pass/fail criteria were established for the CMDA sprinkler tests

- A maximum of 20 sprinklers operate (operating area of 1,600-2,000 square feet)

- Ceiling gas temperatures are such that exposed structural steel would not be endangered

- The fire does not burn to the end of the main test array or jump the aisle and ignite the target arrays

Again palletized storage height of 15 feet of unexpanded Group A plastics was investigated, but in these cases (as compared to the 2007 XL Gaps tests) stored at a ceiling height of 40 feet. The fans were operated at full speed and shutdown after sprinkler activation, immediately shut off in tests, UL-3 and UL-4, and with a 90-second delay in test, UL-5. The first two tests (UL-3, UL-4) utilized two different types of smoke detectors, an air sampling type and an ionization type detector (UL-4), whereas UL-5 test used the sprinkler waterflow as the actuation mechanism.

In all three tests the fires could be controlled by K-11.2 sprinklers – but created large damages to the storage arrays, equivalent to 26, 15, and 32 pallet loads for the tests in UL-3, UL-4, and UL-5 respectively. During the first two tests only 6 (7) sprinklers opened, but UL-5 had 20 sprinklers opening (limit for CMDA to receive a passing grade) – barely passing the test. It must be noted that the location of the ignition source for this test was not considered worst case.

Nevertheless the reviewers were “puzzled” by the test outcomes of the Phase II CMDA tests when compared to the 2007 XL Gaps tests. In the 2007 tests the fan was operated at only 50% and shut off immediately (manually) upon sprinkler activation, while ceiling heights were lower (25 feet). The reviewers speculated that the type of ignitors and flue space widths in addition to water pressure fluctuation in the earlier tests may have been responsible for the differences in the test outcomes. They went as far as pronouncing the 2007 XL Gaps tests as “unreliable.”

Did this Impact the Fire and Building Codes?

The current fire and building codes published by the National Fire Protection Association (NFPA) and International Code Council (ICC) contain no specific language regulating the use of HVLS fans. It is up to the individual municipalities to regulate HVLS fan installations. Nevertheless NFPA does provide some recommendations, which were listed previously. These recommendations agree with FM Global Data Sheet 2-2 for general obstructions.

Why don’t we have access to installation guidelines considering that these fans have been in use for some time now? You need to consider that test data and fire test results have just become available (in 2009 and 2010) and associated codes need to be pushed through the code development process first before they are included in subsequent editions. This process is underway but most likely will take some more time before amendments to the current codes will be published. We can only speculate that this may occur by 2012 (Update: NFPA 13 2013, Chapter 11 includes guidance on the installation of HVLS fans in buildings equipped with sprinklers).

Conclusion

The Use of HVLS fans can present a myriad of fire protection issues for the code practitioner and building owner. Steps must be taken during the various stages of the building project to ensure that fire safety is not comprised.

Beyond the current recommendations by NFPA on the installation and use of HVLS fans, here are additional considerations:

- HVLS fans have an impact on sprinkler effectiveness. Tests have shown that sprinkler effectiveness is reduced in buildings with HVLS fans

- Smoke control and development is different from buildings that do not operate HVLS fans

- Fans need to stop upon early fire detection before or on activation of fire sprinklers – this reduces the impact on fire spread and fire dynamics (ceiling jet), but also minimizes cold smoke generation, while limiting growth of the hot gas layer. The hot gas layer can open additional sprinkler heads that will lower water pressure in the already open heads and as a result can diminish overall sprinkler effectiveness

- The shutdown control of the HVLS system should be linked to automatic detection means. The location and selection of detectors (heat, smoke, and carbon monoxide detection) require expert knowledge until clear guidelines are published in context of HVLS fans

- Because of the large volume of airflow in the floor jet, the performance of smoke detection systems will most likely also be negatively impacted, which needs to be considered when designing these systems

- To help avoid the aforementioned issues possibly interlock all fans to shut down upon actuation of the sprinklers. Fans may need a braking system to stop rotation of their blades in a short period of time. In the case of HVLS fans using variable frequency drive motors, they can be easily programmed to shutoff immediately

- Minimize any additional obstructions, as large HVLS fans are a significant obstruction

- It is expected that fire spread is accelerated in unsprinklered buildings with HVLS fans

In summary HVLS fans are here to stay because they offer building owners and business operators low operating cost, short-term amortization of the equipment, and the reassurance of reducing carbon emissions. When any new technology is introduced there are challenges to be overcome, in particular there is an opportunity for the fire protection industry to achieve the required level of building and occupancy safety for HVLS installations, through further testing and clear guidelines in the installation and operation of these devices.

In this article we have discussed fundamental observations of HVLS fan use and impact under fire conditions. While there are currently no strict fire code requirements, these observations led to recommendations by NFPA which can and should be applied until more detailed guidelines are developed. Until then it is up to the experienced code practitioner to understand the application scenarios at hand and to plan and design fire protection systems that will reliably perform their intended mission.

To this extent, we provided a list of design principles that can be additionally incorporated in building design and construction. It is understood that these guidelines may be used with caution by the expert, as every building situation or storage arrangements will differ and unique challenges will always be present that need to be addressed in a “holistic way”. After all fire safety encompasses all the presented challenges, not just a few. If successfully executed, it will result in safer, more economical and sustainable buildings and building operations.

Update:

NFPA 13 (Installation of Sprinkler Systems), 2013 Edition, released a new set of HVLS installation and design rules based on this series of tests:

- The maximum allowable HVLS fan diameter is 24 feet (8 meters).

- HVLS fans need to be centered between four adjacent sprinklers.

- The distance between the HVLS fan blade and the sprinkler deflector has to be at least 3 feet (0.9 meters) to not interfere with sprinkler activation.

- HVLS fans must be interlocked to shut down immediately upon receiving a water flow signal from the fire alarm system.

Further Reading

1. Assessment of the Effects of Air Movement Created by High Volume/Low Speed Ceiling Fans on Fire Sprinkler Operations, 2009, NFPA

2. HVLS Fans and Sprinkler Operation Phase 1 Research Program, Final Report, February 2009, NFPA

3. High Volume/Low Speed Fan and Sprinkler Operation Phase II Research Program, Final Report, January 2011, NFPA

4. Impact of an HVLS Fan on Sprinkler Performance in Rack Storage Fires, Research Technical Report, January 2011, FM Global

Videos of Phase II Fire Testing (videos referenced by date in FM Global Research Report4)

1. The Impact of a High Volume Low Speed (HVLS) Fan on Sprinkler Performance in Rack Storage Fires (1), 30-Foot Rack Storage, 5th August 2010, FM-1, FM Global

2. The Impact of a High Volume Low Speed (HVLS) Fan on Sprinkler Performance in Rack Storage Fires (2), 30-Foot Rack Storage, 20th August 2010, FM-2, FM Global

3. The Impact of a High Volume Low Speed (HVLS) Fan on Sprinkler Performance in Rack Storage Fires (3), 30-Foot Rack Storage, 2nd September 2010, FM-3, FM Global

4. The Impact of a High Volume Low Speed (HVLS) Fan on Sprinkler Performance in Rack Storage Fires (4), 15-Foot Rack Storage, 2nd December 2010, FM-4, FM Global