GHS Against Fire Codes

There is a better in good chance that the Globally Harmonized System (GHS) will impact your business. Current fire and building codes are based on NFPA standards, which – in some cases – differ from GHS regulations. With the start of key implementation deadlines already behind us, businesses must be aware of the differences and key requirements between these two sets of regulations in order to successfully adapt to this change.

There is a better in good chance that the Globally Harmonized System (GHS) will impact your business. Current fire and building codes are based on NFPA standards, which – in some cases – differ from GHS regulations. With the start of key implementation deadlines already behind us, businesses must be aware of the differences and key requirements between these two sets of regulations in order to successfully adapt to this change.

Background

For several years the United States has participated in developing the GHS. In 2009 the Occupational Safety & Health Administration (OSHA) released its first proposal to modify the current Hazard Communication Standard (HCS) and to align it with the United Nations Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This change in OSHA’s HCS was motivated by the fear that without adopting to the GHS, U.S. chemical manufacturers faced the risk of being shut out of many of the world’s largest markets, including China and most of Europe. In 2012, OSHA revised the HCS, and this change has become known as HazCom 2012.

Key Implementation Dates

| June 1, 2015: | Chemical manufacturers and distributors must complete chemical hazard re-classification and apply GHS styled labels and safety data sheets. |

| December 1, 2015: | Distributors must comply fully with HCS requirements providing a 6-month grace period for shipments of old inventory after June 2015. |

| June 1, 2016: | Employers must be in full compliance with revised HCS. |

Manufacturer of chemicals, had until June 1, 2015, after this date everything produced and shipped needs to comply with the new GHS standards. OSHA requires businesses to be responsible for training employees on the new standards and ensuring the labeling and documentation for the chemicals in the workplace comply with the new standards by June 1, 2016.

Significant Changes in Hazard Labeling – GHS Versus NFPA

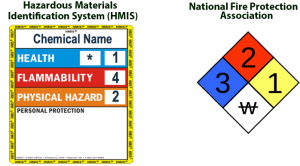

The GHS regulations are new as of June 1, 2015, while NFPA 704 standards have been in use for 60 years in US. As a result, many industries have become familiar with NFPA 704’s so-called ‘Fire Diamond’, and with the method on how different hazards levels are labeled.

NFPA uses four hazard levels with the number four representing the most severe hazard and zero representing no hazard. But GHS uses so-called Hazard Categories, with the number five indicating the lowest hazard and one indicating the most severe.

- NFPA hazard ranking: 0 – 4 with 4 being a HIGH hazard

- GHS hazard ranking: 1 – 5 with 5 being a LOW hazard

Confused? You are not alone. First responders feel discomfort with changing to a completely different numbering strategy used by the GHS. They among many others are used to NFPA’s labeling system, which advises in a familiar manner of the immediate hazards associated with a facility.

Many states and municipalities have adopted NFPA and International Fire Codes as the basis for their local ordinances. These codes and standards continue to require compliance – in addition to the new OSHA regulation using GHS. As of now there is nothing in the planning to integrate GHS regulations into the current fire and building codes.

An issue can arise in storage and warehousing for containers, such as drums, chemical totes and tanks, that serve as the shipping container, as well as the storage container. In these cases, required GHS labeling standards and elements can be applied separately or may be combined with the Fire Code/NFPA required labels. Of course this would mean several labeling elements on one container with each element being based on a different labeling strategy.

So the question remains, should there be two labeling standards, namely GHS and NFPA with such different hazard ranking strategies? NFPA and HMIS (GHS) systems are explicitly allowed under HazCom 2012. In the short term this seems to be the only viable solution. In the long run the need for two simultaneous labeling standards could be reduced to one, as long as the fire and building codes will integrate the new GHS standards.

Changes to the (Material) Safety Data Sheet

GHS is about improving the hazard communication standard (HCS) that OSHA mandates for chemicals in the workplace. That means any potentially hazardous chemical in an office, warehouse, manufacturing area and shipping dock that requires a warning label and a Material Data Safety Sheet (MSDS) may have to be re-classified, relabeled and re-documented with a new Safety Data Sheet (SDS).

MSDS, now simply known as safety data sheets (SDS), extensively changed after adoption of GHS, as all products are now classified for health, environmental, and physical hazards based on GHS criteria. Additionally, the flexibility of format previously permitted for MSDS’s was removed.

GHS requires a standardized 16-part format and will add some additional required content for Safety Data Sheets (SDS) and changes the way that some information is currently reported on MSDS’s.

However, hazardous material classification as required per HMIS and Fire and Building Codes may be impacted by this change. OSHA’s HCS 2012 states the need to reclassify hazardous chemicals. The responsibility for classifying a chemical started with the manufacturers, who needed to complete their HCS 2012 compliance efforts by the June 1, 2015 deadline.

For businesses, the only time a chemical will need to be reclassified if it’s believed that the current information provided with the chemical is insufficient or incorrect. A reclassification may be triggered as the result of performing an inventory analysis and as it is required in the application of regulations based on current fire and building codes. In these reclassification efforts special attention needs to be given to flammable liquids and flammable solids.

Flammable Solids – GHS Versus Fire Code

GHS classifies flammable solids based on their burn rate with further distinction into Category 1 and Category 2 flammable solids based on their resistance to extinguishment by water.

GHS defines a flammable solid as a solid2, “which is readily combustible, or which may cause or contribute to fire through friction. Readily combustible solids are powdered, granular, or pasty chemicals that can be easily ignited by brief contact with an ignition source, such as a burning match, and the resulting flame spreads rapidly. There are two categories of flammable solids: category 1 materials are rapidly burning metals and compounds very resistant to being extinguished by water; category 2 materials are slower burning metals and compounds that are susceptible to extinguishment by water.”

The Fire Code defines a flammable solid as a solid3, “other than a blasting agent or explosive, that is capable of causing fire through friction, absorption of moisture, spontaneous chemical change or retained heat from manufacturing or processing, or which has an ignition temperature below 212°F (100°C) or which burns so vigorously and persistently when ignited as to create a serious hazard. A chemical shall be considered a flammable solid as determined in accordance with the test method of CPSC 16 CFR Part 1500.44, if it ignites and burns with a self-sustained flame at a rate greater than 0.1 inch (2.5 mm) per second along its major axis.”

Table 1. Proposed code change for definition of flammable solids

|

Test Procedure |

Fire Code |

GHS |

|---|---|---|

|

Self-Sustained Burn Rate |

0.1 inches (2.5 mm)/s |

0.0866 inches (2.2 mm)/s |

|

|

Update, IFC 2015: 0.0866 inches (2.2 mm)/s |

|

In the last IFC code development hearings (in 2015), a proposal was made to align the current definition for flammable solids for the next release of the fire code (2015 Edition), see Table 1. This code change was approved. The approved changes are now inline with GHS. The reason provided for this change is that when an (M)SDS is prepared today, a material classified as “Flammable Solids” is typically based on this definition and not the previous definition (existing language in the Fire Code).

Flammable Liquids – GHS Versus Fire Code

As mentioned previously, many states and municipalities have adopted NFPA and International Fire Codes (IFC) as the basis for their local ordinances, this is also the case for ordinances on flammable liquids. Care must be taken to ensure that by complying with the new GHS regulations, this does not create a non-compliance situation with local ordinances; in particular with NFPA 30, Flammable and Combustible Liquids Code, maintaining the original definition of flammable and combustible liquids.

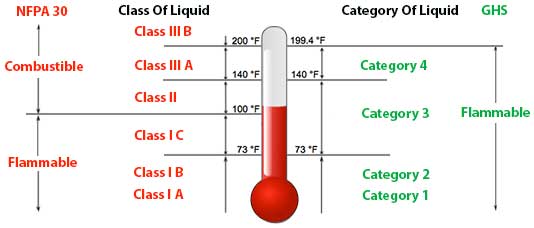

NFPA 30, classifies flammable liquids into six classes – Class I-A, I-B, I-C, II, III-A to III-B. Dividing them into flammable and combustible based on their flashpoint temperatures.

GHS (OSHA CFR 29 1910.106) classifies flammable liquids as “any liquid having a flashpoint at or below 199.4°F” Furthermore they are divided into four categories according to their flashpoint temperature, see Figure 1.

Noteworthy changes are:

| GHS – No Definition Of Combustible Liquids | GHS made obsolete the term “combustible” and now refers to all liquids as “flammable”. NFPA defines flammable liquids as liquids that have a flash point at or below normal operating temperatures (100 °F). “This flash point was selected as the basis for classification of flammable versus combustible liquids, because it is directly related to a liquid’s ability to generate vapor. Since it is the vapor of the liquid, not the liquid itself that burns, vapor generation becomes the primary factor in determining the fire hazard. Liquids having flash points below ambient storage temperatures generally display a rapid rate of flame spread over the surface of the liquid, since it is not necessary for the heat of the fire to expend its energy in heating the liquid to generate more vapor1.” Combustible liquids are defined as liquids that generate vapors above normal operating temperatures. This dileneation in ‘vapor volatility’ is crucial in deciding on the appropriate means of fire protection. |

| GHS – Class III B Liquids Are No Longer Classified | GHS no longer classifies the risk of storing these liquids. Class III B liquids include benzyl alcohol, hydraulic fluids, vegetable oils, ethylene glycol, glycerin, and others. Fire codes continue to show concern for the fire risk of these liquids and the dangers of storing them. |

| GHS – Category 4 Flashpoint Lower Than Class III B Flashpoint | The ‘lower-threshold’ (200 °F) flashpoint of Class III B liquids is theoretically larger than the ‘cut-off threshold’ flashpoint (199.4 °F) of Category 4 liquids. However, the fire codes specify a 93° C for the lower-threshold value of Class III B liquid flashpoint, which is the same flashpoint temperature called out for the cut-off threshold of Category 4 liquids under the GHS system. So in Celsius there is no difference between these two threshold values. |

| GHS – Different Boiling Points for Category 1 and 2 | Boiling point of liquids dividing Class 1A & 1B, now Category 1 & Category 2, is now 95°F for GHS, while in the fire codes it is set at 100°F between Class 1A & 1B. |

| GHS – Category Versus Class Confusion | There is a danger of misinterpreting Category 2 as Class II. A liquid’s Category or Class must be verbally connected to the classification system (GHS or NFPA) to which it is referenced in order to avoid misinterpretation. Class II and Category 2 liquids show very different vapor volatility and require different means of fire protection. |

| • Category 2 includes liquids having flashpoints below 73.4°F and having a boiling point above 95°F. • Class II Liquid — Any liquid that has a flash point at or above 100°F |

References

[1] OSHA, Flammable and Combustible Liquids, 29 CFR 1910.106, Training and Reference Materials Library, www.osha.gov[2] Globally Harmonized System of Classification and Labelling of Chemicals, wikipedia.org

[3] Flammable Solids, 2012 International Fire Code, Chapter 36, International Code Council