Distillery Storage Dilemmas

Fire code professionals, businesses and building owners are facing the dilemma on how to successfully address fire protection issues when working on distilleries and storage of distilled goods. NFPA Standards and Fire Codes provide only some of the answers. Despite a considerable number of fire tests and subsequent advancements in the fire and building codes, there is still a need to creatively resolve many of the remaining unanswered questions.

Fire code professionals, businesses and building owners are facing the dilemma on how to successfully address fire protection issues when working on distilleries and storage of distilled goods. NFPA Standards and Fire Codes provide only some of the answers. Despite a considerable number of fire tests and subsequent advancements in the fire and building codes, there is still a need to creatively resolve many of the remaining unanswered questions.

FM Global (FM) has performed a new series of full-scale fire tests1 for protecting storage of distilled goods in glass bottles in cartons (see below). Conclusions drawn from these fire tests may help develop practical solutions in the protection of these types of goods – potentially solving some of the dilemmas at hand.

| Question: | The International Fire Code exempts the storage of ‘alcoholic beverages in wooden casks.’ Does this exception imply that these alcoholic beverages will never be treated as hazardous materials storage? In other words, do only NFPA 13 and Chapter 32 of the Fire Code apply? Will the maximum allowable quantities be unlimited? | ||||||||||||||||||||||||||||||||

| Answer: | A recent staff interpretation and code commentary7 recognizes this exception in the fire code. However, it states that since the building code includes the same Maximum Allowable Quantities (MAQs), but has no exception for alcoholic beverages in wood barrels, then the MAQs do apply. In short the hazardous materials requirements in the Fire Codes do not apply, while the hazardous materials requirements in the Building Codes do apply.

For example when MAQs for storage in wood barrels are exceeded, the occupancy will become an H-occupancy and the building code requirements, such as allowable area, and occupancy separation, among other requirements in the International Building Code (IBC) do apply. Note: Most of the current state fire and building codes are based on the International Fire and Building Codes published by the International Code Council (ICC). They can differ from the ICC published versions by state adopted code amendments. | ||||||||||||||||||||||||||||||||

| Question: | For my micro distillery I plan on storing a few barrels of distilled liquor onsite, should I be considered an H-Occupancy? How extensive is a build out of an H-occupancy storage room? | ||||||||||||||||||||||||||||||||

| Answer: | The International Building Code allows businesses to store up to 240 Gallons of distilled liquor in a sprinklered building (120 Gallons in an unsprinklered building) without being considered high hazard occupancy (H-occupancy). If you move the barrel storage into a separate room build out as an H3-occupancy, then you will be allowed to store four times the amount of distilled liquor, or 1000 Gallons (without the need for spill control) for steel barrels and, though not recommended, unlimited amounts for wood barrels.

Addressing your second question, no, it may not be a big deal to create an H-occupancy storage room. The fire and building code requirements in this case (small storage room for distilled liquor) for H3-occupancy are not very high. If we assume that allowable areas is not an issue, the only requirements are ventilation of one cubic foot per minute per square foot of storage area, backup power, 1-hour rated walls and doors, and an automatic sprinkler system for steel barrel storage. Only 1-hour rated walls and an automatic sprinkler system are required for wood barrel storage. These requirements are summarized in Table 1. Table 1. Distillery Storage Requirements

Let’s be more specific. For a small storage room, ventilation results in installing a wall mounted exhaust fan near the floor and vented to the outside**. While the fan will have to have backup power, due to its small size battery backup may suffice. The storage room will have to have 1-hour rated walls and doors and an automatic sprinkler system. Many rooms are already considered 1-hour rated, and therefore no changes are required (all wall penetrations have to be 1-hour rated). A 1-hour fire rated door may have to be added, or already exists. Upgrading automatic sprinkler systems for a small storage room may be as little as changing out a few sprinkler heads. Sprinkler design densities will depend on storage height, storage method, container type and size and ceiling height. The advantages of having a separate storage room go far beyond the need for fire or hazard protection:

** Wooden barrels are exempt in the fire code, which means no ventilation is required. However, ventilation is strongly recommended for H-occupancies due to evaporation out of the barrels (“Angels’ Share”). It is up to the AHJ (Authority Having Jurisdiction) to determine applicable requirements. If ventilation is required and continuous ventilation in wood barrel storage is of concern based on excessive evaporation out of the barrels affecting flavor and reducing amounts, a Lower Flammable Limit sensor can be installed. The sensor causes the start of ventilation only when vapor fumes exceed 25% of their flammable limit. This can help minimize risks from vapors within the room (“Angels’ Share”). This proposed exhaust/ sensor approach is not in the codes and therefore may need to be approved by the AHJ. |

||||||||||||||||||||||||||||||||

| Question: | Does the building or fire code make an exception for distilled goods in consumer packaging? Would a finished product (90 proof bottles in cases on pallets) stored in a warehouse at the distillery still be considered an H-3 occupancy? | ||||||||||||||||||||||||||||||||

| Answer: | There are exemptions in the fire and building codes 5,6 specifically for retail and wholesale occupancies. But note that these exemptions do not apply for general warehousing. The exemptions in the fire and building codes are found in Table 5003.1.1(1) (Fire Code) and Table 307.1(1) (Building Code) and they may apply if you store the finished goods not exceeding 1.3 gallons per individual container. As always, it is up to the AHJ to determine all the requirements that need to be complied with. | ||||||||||||||||||||||||||||||||

| Question: | Should dry ingredients be considered combustible dust? | ||||||||||||||||||||||||||||||||

| Answer: | Combustible dust is defined as follows by the Fire Code:

There is a size limitation in this definition. The Fire Code will not classify anything greater than 420 microns as combustible dust. Additionally, after the dust is wetted, the dry ingredients are no longer considered combustible dust. However, with most dry ingredients some portion of the material will be small enough (similar to the bottom of a cereal box) to be considered less than 420 microns. The current definition in NFPA 654 2 is “a combustible particulate solid that presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape.” Again the reasoning here is that material can break down during shipping, conveying, mixing, and use. It will then become an immediate hazard in its dust form, if a source of ignition is available. Therefore dry combustible dust does exist in (breweries and) distilleries, especially when these dry ingredients are being poured into tanks to make “mash”. Fire departments typically require dust collectors in areas where dry ingredients are being dispensed. Additionally housekeeping, which is more commonly maintained in a distillery than a standard industrial occupancy, is critical to keeping the dry dust on surfaces to a minimum. Why is dry dust on surfaces critical since only suspended dust in air creates an explosion hazard? Major dust explosions typically occur as a secondary incident. Usually a smaller incident caused by air turbulence creates a disturbance of the dust particles, suspending them into air. Once suspended in air, a secondary incident occurs when the dust mixed with air reaches an ignition source resulting in an explosion. An example of an investigation to evaluate the potential of a dust explosion hazard in a distillery is discussed in detail in the article “Assessing Combustible Dust – New Codes”. The straightforward calculations are based on the ‘layer depth criterion method’ prescribed in NFPA 654 and use floor dust layer thickness and area of the dust accumulations as inputs. | ||||||||||||||||||||||||||||||||

| Question: | How should we design a fire sprinkler system when full-scale fire test results conflict with commodity classifications for 100-proof alcohol? | ||||||||||||||||||||||||||||||||

| Answer: | NFPA 13 3 requires 100-proof alcohol (cartoned in 1 GAL or less glass containers) to be protected as Class III for rack storage and Class IV for palletized storage (Table A.5.6.3.4, footnote ‘b’). The Fire Code specifies a Class IV commodity class. However, results from FM Global’s latest series of fire tests on 100-proof alcohol in high piled storage put in question NFPA’s and the Fire Code’s commodity classifications. What commodity class should the design be based on?

Before we attempt to address this question, let us provide some background on the commodity classification of the Fire Code to specify the necessary sprinkler protection scheme: Two sets of regulations typically apply to palletized or rack storage of flammable liquids; high piled storage regulations and hazardous materials regulations. Depending on whether the AHJ (Authority Having Jurisdiction) allows the storage to fall under the exemptions called out in the Fire Code 4,5 (Section 5001.1 and Section 5701.2), the hazardous materials regulations, may not need to be applied. If the exemptions are not deemed applicable, the more stringent requirements of both hazardous materials protection regulations and high piled storage regulations have to be applied. But if the storage is exempted out of the hazardous materials chapters of the Fire Code, how well do the protection schemes in the high piled storage chapter perform in the event of a fire? Can this storage truly be treated, and adequately protected, as a Class IV commodity? Let’s look at two specific examples and compare the sprinkler requirements to the results of the FM fire tests: A sprinklered building and 100-proof distilled goods filled in glass bottles and packaged in cartons stored in the following configurations:

Per NFPA 13 protecting storage in palletized or rack storage configurations requires the following ceiling densities when CMDA (Control Mode Density Area) sprinkler protection is applied:

For palletized storage these Class IV design densities, 0.22 (0.29) gpm/ft2 over 2000 ft2, are significantly lower than what FM Global successfully tested1 in the latest series of fire testing (0.6 gpm/ft2 operated 13 sprinklers while the fire propagated to the extent of the test storage array). This poses the question of whether palletized storage can be adequately protected despite the much lower design densities governed by Class IV protection requirements. In the case of protecting the same goods in rack storage array, NFPA 13 prescribes sprinkler protection that are based on a classification of Class III, with in-rack sprinklers every 10 feet or 15 and 25 feet vertically, and a ceiling density of 0.3 (0.4) gpm/ft2 over 2000 ft2. This protection scheme is similar to what FM successfully tested (the in-rack sprinklers controlled the fire). Therefore protecting distilled goods in rack storage classified as Class III commodities to the configuration tested appears adequate. It is expected that applying the Fire Code’s mandated Class IV protection scheme, which requires in-rack sprinklers every 15 feet vertically and a ceiling density of 0.35 (0.45) gpm/ft2 over 2000 ft2, in addition to face sprinklers or horizontal barriers, will provide even better protection. However, how the protection compares for lower rack storage heights, where no in-rack sprinklers are required, remains unanswered. |

FM Global Fire Testing Of Distilled Goods In Storage

In the latest efforts in addressing questions on how to protect stored distilled goods, Factory Mutual Global performed a series of fire tests1. The objective for these tests was to develop new protection options for ‘diluted water miscible ignitable liquids’ in glass bottles, which are stored in palletized and rack storage configurations. Palletized storage was tested with ceiling only sprinkler protection, whereas rack storage was tested with ceiling and in-rack sprinkler protection.

Each glass bottle in the test setup contained 1.75 L (59 fl. oz.) of 50% (v/v) denatured alcohol, 100-proof. According to FM the liquid is classified as a Group 3 liquid (NFPA classifies it as a 1C Flammable Liquid based on a flash point of 75 degrees F). Six bottles per industry-standard carton were stored in a 36-carton per pallet configuration, 55 inches tall. Stretch wrap was applied around the side of the cartons to ensure stability of the pile.

Palletized Test Configuration

Each of these pallet loads were stored side by side with 12-in longitudinal flues and no transverse flues to a storage height of 16.5 ft. K-14 upright Quick Response (QR) sprinklers were used for a ceiling-only protection scheme with ceiling heights of 30 ft and 40 ft. Applied sprinkler ceiling densities were:

- 0.6 gpm/ft2 and 1.0 gpm/ft2 for the 30-ft ceiling height,

- 1.2 gpm/ft2 for the 40-ft ceiling height.

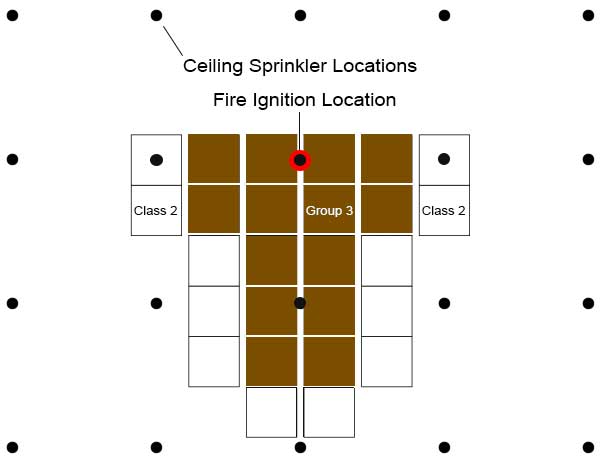

Figure 1. Plan View: Palletized storage arrangement of pallet loads of Group 3 liquids surrounded by pallet loads of Class II commodities to assess fire propagation

Additionally pallet loads of corrugated paper cartons, Class 2 commodities, with non-combustible sheet metal liner on the inside were stacked at the periphery of the test arrays to evaluate fire propagation.

Fire test results demonstrated that with a ceiling density of 0.6 gpm/ft2 the palletized stack collapsed and a total of 13 ceiling sprinklers were operating. The fire propagated to the extent of the array and was extinguished at test termination. Increasing the ceiling density to 1 gpm/ft2 resulted in only 1 sprinkler operating with no stack collapse. Further increasing ceiling density to 1.2 gpm/ft2 and increasing the ceiling height to 40 ft resulted in 3 ceiling sprinklers operating with the palletized stack collapsing during this test.

Rack Storage Test Configuration

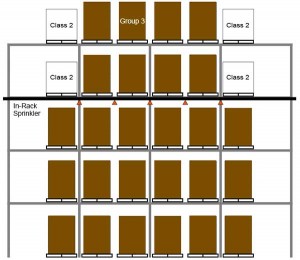

Each of the pallet loads was stored side by side with 6-in transverse flues to a storage height of 30 ft with a 35-ft ceiling height. In-rack sprinklers were installed at 18-ft elevation with 12 ft of storage above the in-rack sprinklers protected by ceiling sprinklers only. K-8.0 in-rack sprinkler were used during this test and operated with a minimum flow of 30 gpm. Ceiling protection was based on K-11.2 with a water pressure of 28 psi.

Figure 2. Elevation View: Rack storage arrangement with in-rack sprinklers at 18 feet, pallets of Group 3 liquids and pallets of Class II commodities to assess fire propagation.

The fire test demonstrated that the fire was controlled with two in-rack sprinklers operating. There was no fire propagation above the in-racks and no ceiling sprinklers were operated. The fire was contained to the ignition area.

Overall Test Conclusions

Cartoned alcohol in 1.75 L glass bottles can be successfully protected in palletized and rack storage configurations. In the case of palletized storage, it can be expected that the stack will collapse in most cases. Floor level pool fires are protected even at lower (ceiling) sprinkler pressures and resulting water flows (0.6 gpm/ft2). In-rack sprinklers at 18-ft increments successfully protected pallet loads in a rack storage configuration.

Based on these results FM Global in 2014 updated Data Sheet 7-29, Ignitable Liquid Storage in Portable Containers, and included new protection options for Group 3 water-miscible liquid in 59 oz (1.75 L) plastic and glass bottles in both palletized and in-rack storage configurations.

The article was originally published on Feb 25th 2015 and updated on May 5th 2016

References:

[1] Distilled Spirits Cased Goods Storage, Seth Sienkiewicz, FM Global, Global Research Update: High Challenge Storage Protection, May 22nd 2014, London, England

[2] NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, National Fire Protection Association, Quincy, MA, 2013

[3] NFPA 13, Standard for the Installation of Sprinkler Systems, National Fire Protection Association, Quincy, MA, 2013

[4] California Fire Code 2013, California Code of Regulations, Title 24, Part 9, Based on the 2012 International Fire Code, California Building Standards Commission, Sacramento, CA, 2013

[5] International Fire Code 2015, International Code Council, 2014

[6] International Building Code 2015, International Code Council, 2014

[7] International Fire Code 2012, Code and Commentary, International Code Council, 2012