New ESFR Obstruction Test Results

NFPA’s Fire Protection Research Foundation (FPRF) initiated a two-phase study on the effects of obstructions on the ESFR sprinkler system’s ability to suppress fires. Phase one, which was primarily a literature review on the topic, was completed in 2014 and the fire test results from the second phase are now published. The tests were performed on Group A Plastics in rack storage configurations protected by K-17 ESFR sprinklers.

NFPA’s Fire Protection Research Foundation (FPRF) initiated a two-phase study on the effects of obstructions on the ESFR sprinkler system’s ability to suppress fires. Phase one, which was primarily a literature review on the topic, was completed in 2014 and the fire test results from the second phase are now published. The tests were performed on Group A Plastics in rack storage configurations protected by K-17 ESFR sprinklers.

It was shown that steel bar joists and steel bridging members can adversely affect the fire suppression efficacy of ESFR sprinkler systems, especially if obstructions are mounted within 8 inches beneath the discharge nozzles.

Update: The Fire Protection Research Foundation of NFPA published a webinar video discussing the full-scale fire test results on ESFR obstructions.

ESFR Sprinkler Obstructions

Early Suppression Fast Response (ESFR) sprinklers are commonplace in the protection of warehouses. The main differences, when compared to standard sprinkler systems, are the large amount of water dispersed (in the event of a fire) and the water discharge patterns. The ESFR sprinkler system’s biggest advantage is that it not only controls the fire, as is the case with standard sprinkler systems, but also suppresses it – often making it unnecessary for the fire department to intervene. However, obstructions impacting the sprinkler discharge pattern can affect the ability of the ESFR sprinkler system to suppress the fires.

Sprinkler system designers and installers have to worry about various types of obstructions consisting of both supporting and non-supporting structural members, with the latter including lights, plumbing, piping, gas lines, cable trays, conduits for electrical wiring and ductwork. Therefore, it is expected that the results from full-scale testing can be used to expand knowledge concerning acceptable thresholds for ESFR sprinkler systems with a variety of obstructions. This will allow for quantifying the effects of obstructions on ESFR performance and ultimately produce safer designs and sprinkler installations.

NFPA 13 Requirements For ESFR Installations With Obstructions

Current ESFR obstruction regulations require (with respect to storage height and supporting structural members):1,3

- To place the sprinklers a minimum of 12 inches horizontally from the nearest edge of any bottom chord or bar joist.

- Bridging members of 2 inches or less in width are to be located a minimum of 24 inches below the elevation of the sprinkler deflector, or positioned a minimum of 12 inches horizontally from the sprinkler deflector.

- NFPA 13 limits the height of storage from being within 36 inches of the ESFR sprinkler deflector.

For obstructions based on non-supporting structural members, general rules on obstruction apply (NFPA 13 Sections 8.12.5.1-3). Obstructions are allowed if:3

- Isolated obstructions are less than 2 feet wide and 1 foot or more horizontally from the sprinkler

- Isolated and continuous obstructions are less than 2 inches wide and 2 feet or more below the sprinkler deflector, or 1 foot or more horizontally from the sprinkler

- Continuous obstructions are 1 foot or less in width and located 1 foot horizontally from the sprinkler

- Continuous obstructions are 2 feet or less in width and located 2 feet horizontally from the sprinkler

If the obstruction does not satisfy any one of these requirements, NFPA 13 offers two potential solutions: eliminating the obstruction or adding sprinklers underneath the obstruction.

Storage Configurations Tested

All tests were based on a nominal storage height of 30 feet and a ceiling height of 40 feet. Rack storage areas consisted of double-row racks and two single-row racks separated by four-foot aisles on both sides. The tested commodity was cartoned unexpanded Group A Plastics.

K-17 ESFR sprinklers were selected for the fire tests, and were obstructed by (1) bar joists only and (2) a combination of bar joists and bridging members. ESFR sprinklers were spaced 10 feet apart and operated at two discharge pressures, 50 psi and 75 psi.

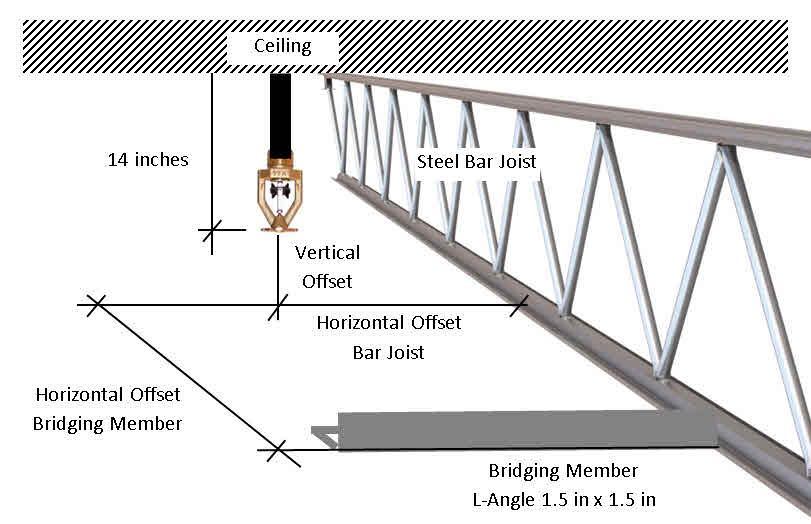

Dimensions of the bar joists and bridging members applied during these tests are typical for warehouse construction. For spans exceeding 60 feet, the selected joist depth was 36 inches. Smaller spans were represented by joist depths of 22 inches. The most commonly found joist depth that was tested was 30 inches. Joists may also be reinforced with bridging members made from one to two inch angle iron, providing lateral stability. Therefore some of the tests included bridging members, as a secondary obstruction, and in addition to bar joists, as shown in Figure 1.

Fire Test Results

The test series results, detailed in Table 1, showed the following:2

- In general, the larger the depth of the bar joists, the lesser the effect of the bar joist on sprinkler performance. This is due to the bottom chord of the joist being further away from the sprinkler.

– A 3 inch horizontal offset on a 30-inch deep steel bar joist with no secondary

obstruction activated the maximum permissible (12) sprinklers for a pass (Test #2)

– A 6 inch horizontal offset on a 36-inch deep steel bar joist with no secondary

obstruction (bridging member) activated only 3 sprinklers (Test #1)

- Bridging members were ‘shown to be challenging’ (meaning: expect potential system failures) if located 8 inches or less directly below the sprinkler deflector (Failed Test #5)

- Bridging members located 8 inches below the sprinkler deflector and a minimum of 2.5 inches horizontally from the centerline of the ESFR sprinkler, were found to not pose a significant challenge.

Table 1. Fire Test Configurations and Results

| Fire Test | |||||

|---|---|---|---|---|---|

| Primary Obstruction | 36 inch deep steel joist, edge of lower chord 6 inches from centerline of sprinkler | 30 inch deep steel joist, edge of lower chord 3 inches from centerline of sprinkler | 36 inch deep steel joist, edge of lower chord 6 inches from centerline of sprinkler | 36 inch deep steel joist, edge of lower chord 6 inches from centerline of sprinkler | 22 inch deep steel joist, edge of lower chord 6 inches from centerline of sprinkler |

| Secondary Obstruction | 1.5 inches by 1.5 inches bridging member, 1.5 inches horizontal offset from sprinkler | 1.5 inches by 1.5 inches bridging member, centered below sprinkler | 1.5 inches by 1.5 inches bridging member, 1.5 inches horizontal offset from sprinkler |

||

| Number of Operated Sprinklers | |||||

| Result |

From the full-scale fire tests that were conducted, the following conclusions have been drawn:

- A K-17 ESFR sprinkler obstructed by a bar joist with a 6-inch offset from the closest edge of the obstruction and without a horizontal bridging member produced acceptable results.

- A K-17 ESFR sprinkler obstructed by a bar joist with a 3-inch offset from the closest edge of the obstruction and without a horizontal bridging member controlled the fire with 12 activated sprinklers.

- Tests showed that regardless of the horizontal offset, a bridging member with a vertical separation of 19.5 inches on a 36-inch deep bar joist with a 6-inch offset provides acceptable results.

- One test failed (Test 5). The failure of this test can be attributed to the vertical proximity of the bridging member to the sprinkler. This test illustrated that a bridging member directly underneath the sprinkler with a vertical separation of 6 inches produced unacceptable results

- The fire growth rates discussed in the report (Section 8.3) show that the fire in one of the tests (Test 2) was not comparable to the other four fires and should be repeated.

Summary

Information gathered from these tests will be used as a technical basis for the NFPA 13 Technical Committees to develop new requirements and guidelines for ESFR sprinklers. However, given the advanced stage of publication of NFPA 13 2016 Edition, new requirements based on these test results will not be included in the upcoming revision of the standard.

References

[1] Obstructions and ESFR Sprinklers – Phase 1, Final Report, The Fire Protection Research Foundation, October 2014, One Batterymarch Park, Quincy, MA [2] Obstructions and ESFR Sprinklers – Phase 2, Final Report, The Fire Protection Research Foundation, September 2015, One Batterymarch Park, Quincy, MA [3] NFPA 13, Standard for the Installation of Sprinkler Systems, 2013 Edition, NFPA, One Batterymarch Park, Quincy, MA