Sprinkler Protection Under Sloped Ceilings

NFPA’s Fire Protection Research Foundation (FPRF) initiated a project to determine the impact of sloped ceilings on the protection of storage with ceiling slopes steeper than 2-in-12 (equivalent to 9.5 degrees). As part of this effort, FM Global was tasked to conduct fire simulations to better understand issues and risks associated with storage under sloped ceilings. The results of these sprinkler activation and suppression analyses have now been released by FM Global.

NFPA’s Fire Protection Research Foundation (FPRF) initiated a project to determine the impact of sloped ceilings on the protection of storage with ceiling slopes steeper than 2-in-12 (equivalent to 9.5 degrees). As part of this effort, FM Global was tasked to conduct fire simulations to better understand issues and risks associated with storage under sloped ceilings. The results of these sprinkler activation and suppression analyses have now been released by FM Global.

Update December 2020: For updated information and final guidance FM Global and NFPA’s FPRF published the results of Phase III fire testing in a final research report on storage under sloped ceilings larger than 2 in 12. See this article for a summary of this report.

Several parameters impact protection criteria including the slope of the ceiling, the commodity being stored, the types of sprinklers (including ESFRs), sprinkler orientation, and sprinkler spacing. As of now, possible protection design solutions to sloped ceilings suggest making use of higher sprinkler densities or larger calculation areas for non-storage applications.

NFPA 131 limits protection for storage applications to ceiling inclination slopes of no more than 2-in-12. To potentially overcome this limitation, higher roof slopes were investigated by the Fire Protection Research Foundation, which commissioned numerical analyses and full scale fire tests to gather detailed insights of ceiling slope effects on sprinkler performance. The conclusions drawn from these tests will be used to develop the technical basis for the NFPA 13 Technical Committees for new requirements and guidance.

Current Standards – FM Global and NFPA 13

FM Global requires ceiling inclines to be less than 10 degrees (approx. a 2-in-12 slope), if in-rack sprinklers are not installed. Rack storage protection for these ceiling angles are based on the presence of excessive clearances, as prescribed in FM Global Data Sheet 8-9, Storage of Class 1,2,3,4 and Plastic Commodities.2 A continuous false ceiling is recommended once inclination angles exceed 10 degrees. Sprinkler deflector orientation is outlined by FM Global Data Sheet 2-0, Installation Guidelines for Automatic Sprinklers,3 and requires parallel-to-the-floor installation.

NFPA 13 also requires the use of false or dropped ceilings, if ceiling inclines exceed 2-in-12 slopes. However, NFPA 13 requires sprinkler deflectors to have parallel-to-the-ceiling mounting.

Study Description

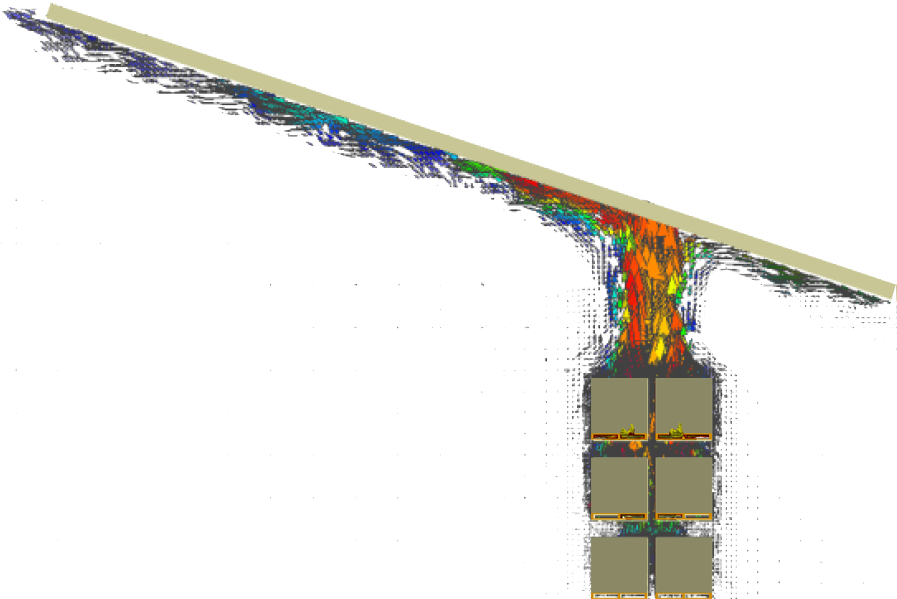

In order to assess the impact of sloped ceilings on the capability of fire protection systems, a numerical model based on FireFOAM (FM Global’s fire modelling software) was developed to simulate fire induced heat flows under sloped ceilings, Figure 1. The numerical results on the effects of various ceiling inclinations were compared to (small-scale) experimental data.

The goal of these studies4 was to evaluate sprinkler activation times and dispersed water flux patterns of commodities stored under sloped ceilings with various roof slopes – ranging from zero degrees to 33 degrees (8-in-12 slope). The commodities – cartoned unexpanded plastics – were stored in a 3-tier high rack storage configuration. Ceiling clearances applied (distance from top of storage to ceiling) were 10 feet and 20 feet. The sprinkler deflector orientations investigated were parallel-to-the-inclined-roof and parallel-to-the-floor-surface. The sprinkler types that were studied included quick-response, ordinary temperature, standard response and high-temperature sprinklers.

Sprinkler activation time studies were separately investigated from water (flux) distribution pattern. This was done to isolate activation patterns from suppression phenomena. Water distribution patterns were based on K-14 pendent sprinklers at 50 psi activated under fixed heat-release fire sources (not based on growing fires, as assumed in the activation studies). Results were based on the activation of one and four sprinklers on top of the rack storage array for various ceiling inclinations and sprinkler deflector orientations.

Results

Slopped Ceiling Flow Validation

Figure 1. Heat Flow Simulation of Cartoned Unexpanded Plastics in Rack Storage Under Sloped Ceiling of 18 Degrees (Image Credit 4)

The ability of FireFOAM to accurately predict ceiling jets was validated by data from small-scale experiments with a Heptane fuel source (average heat release rate of 20 kW) located three feet under an 8 ft. x 8ft. ceiling area with inclination angles set at 0⁰, 10⁰, 20⁰, and 30⁰, respectively.

The results of the numerical models showed a good correlation between the predicted and actual experimental temperature rises. The validated model configuration was then applied to large-scale simulations. For the case of horizontal ceilings, the model predicts flames to impinge on the ceiling in around 50 seconds, and at 100 seconds the entire rack storage configuration is on fire.

Sprinkler Activation Times

-

- Quick-Response, Ordinary Temperature Sprinklers: For inclination angles up to 18 degrees (equivalent to a 4-in-12 or a 1-in-3 roof slope), sprinkler activation times are not considerably impacted and are generally similar to activation times from horizontal ceilings. Increasing the inclination angle to 26 degrees (equivalent to a 6-in-12 roof slope) produced significant delays in activation. Angles over 26 degrees resulted in even longer activation times and an increased number of sprinklers activated on the elevated side compared to the number of sprinklers activated on the lower side (referred to as ‘activation time pattern skewness’). Increasing the ceiling clearance from 10 feet to 20 feet increases sprinkler activation times by three seconds.

-

- Standard Response, High-Temperature Sprinklers: Activation times increase for this type of sprinkler compared to the previous sprinkler type. At an 18 degree inclination, four more sprinklers activated on the elevated side than on the lower side. This ‘activation time pattern skewness’ was not observed with quick-response, ordinary temperature sprinklers at 18 degrees. Increasing the ceiling clearance from 10 feet to 20 feet increases activation times by five seconds.

Water Flux Distribution Patterns

-

- The deflector orientation strongly affects the water flux reaching the fire source and the wetting region. As the ceiling inclination increases, water flux on top of the commodity is reduced when sprinkler deflectors are placed parallel to the ceiling. However, the parallel-to-the-floor deflector orientation produced a fairly constant water flux to the fire region under the same roof inclinations.

-

- For inclinations of 18 degrees and below, the results are less sensitive to sprinkler orientations. At an 18 degree roof angle, a 25% lower water flux was predicted for the parallel-to-the-ceiling deflector orientation. At higher roof angles, the actual location of the fire source relative to the sprinkler locations produced increasingly skewed and decreased water flux patterns (including a higher number of sprinklers activated). For the 33 degree roof inclination (equivalent to an 8-in-12 roof slope), the water flux on top of the fire source is reduced by 50 % (with parallel-to-the-ceiling deflector) compared to the horizontal case.

Conclusions

The numerical analyses demonstrated the adverse effects of roof inclination angles on sprinkler activation times and water flux distribution patterns.

The results showed that

-

- Up to 18 degrees of roof inclination from horizontal (equivalent to a 4-in-12 roof slope), sprinkler activation times are not considerably impacted.

-

- Applying standard response, high-temperature sprinklers, as opposed to quick-response, ordinary temperature sprinklers, will increase activation times.

-

- Increasing ceiling clearances for these test cases from 10 feet to 20 feet will slightly increase activation times (between three to five seconds).

-

- Sprinkler deflector orientations parallel-to-the-floor is preferable, as it provides the best possible water flux to the fire region.

The conclusions drawn from these studies need to be verified by full-scale fire tests, currently being conducted by NFPA’s FPRF. It is expected that the conclusions drawn from these tests will be considered for the release of the 2019 edition of NFPA 13 and an update of FM Global’s Protection Loss Data Sheets.

References

[1] NFPA 13, Standard for the Installation of Sprinkler Systems, 2013 Edition, National Fire Protection Association, Quincy, MA, 2013 [2] FM Global Data Sheet 8-9, Storage of Class 1,2,3,4 and Plastic Commodities, FM Global, Norwood, MA, July 2011 [3] FM Global Data Sheet 2-0, Installation Guidelines for Automatic Sprinklers, FM Global, Norwood, MA, January 2014 [4] Numerical Modeling of Sprinkler Activations and Spray Transport Under Sloped Ceilings, Prateep Chatterjee, Karl V. Meredith, FM Global, Norwood, MA, November 2015